- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

- All Product Highlights

- QM-Fit

- SmartMeasure-AL

- SJ-220

- QuantuMike

- LEGEX Takumi

- STRATO-Active Series

- Measurlink 10

- TAGLENS

- MCOSMOS 5

- Crysta Apex V

- FORMTRACER Avant

- MiSTAR 555

- Calipers

- Bluetooth Data Transmission

- QuickVision Pro

- All Products by Industry

- Aerospace

- Medical

- Automotive

- Energy

- Gen. Manufacturing

- Electronics

- Original Equipment Manufacturers (OEM)

- Case Studies

- All Small Tools

- Calipers

- Micrometers & Micrometer heads

- Inside Measuring Instruments

- Depth Measuring Instruments

- Height Gauges

- Indicators & Caliper Gauges

- Auxiliary Equipment and Miscellaneous

- Calibration Instruments

- Gauge Blocks

- All CMM

- Small & Medium sized CMMs

- In-line & Shopfloor CMMs

- Large sized CMMs

- CMM Rotary Tables

- Probes

- Styli

- Fixtures

- CMM Accessories

- CMM Software

- SmartMeasure-AL

- All Vision

- Manual 2D Vision Measuring Machines QM-Fit

- Manual 2D Vision Measuring Machines Quick Image

- Manual 3D Vision Systems

- 3D CNC Vision Systems

- 3D CNC Multi-sensor Vision Systems

- 3D CNC Micro Geometry Vision Systems

- Vision System Software

- Accessories for Vision Machines

- Vision System Fixtures

- Vision System Styli

- All Optical

- Magnifiers

- Measuring Projectors

- Measuring Microscopes

- Microscope Units

- Interferometer Units

- Objective Lenses

- M2 for Measuring Microscopes and Projectors

- TAGLENS

- Optical Measurement Fixtures

- All Hardness

- Softwares for Hardness Testing Machines

- Portable Hardness Testers

- Hardness Reference Materials and Indenters

- Rockwell Hardness Testing Machines

- Vickers Hardness Testing Machines

- Micro-Vickers Hardness Testing Machines

- All Sensors

- Linear Gauges

- Low Force Gauges

- Counters and Display Units

- Laser Scan Micrometers

- Surface Measure

- Sensor Management Software

- Micrometers & Micrometer heads

- Digital & Mechanical Micrometers

- Micrometer Accessories

- Micrometer Heads

- Micrometer Head Accessories

- Inside Measuring Instruments

- Inside Micrometers

- Bore Gauges

- Inside Micrometer & Bore Gauge Accessories

- Indicators & Caliper Gauges

- Digital Indicators

- Indicator Accessories

- Lever Indicators

- Dial Indicators

- Dial Test Indicators Accessories

- Thickness, Caliper & Tension Gauges

- Auxiliary Equipment and Miscellaneous

- Indicator Stands

- Precision Vices

- Plates and Granite Squares

- Angle Measurement and Squares

- Feeler Gauges, Rules, Knife Edges

- Gauge Blocks

- Steel Gauge Block Sets

- Steel Individual Gauge Blocks

- Ceramic Gauge Block Sets

- Ceramic Individual Gauge Blocks

- Special Gauge Blocks

- Gauge Block Accessories

- Accessories for Square Gauge Blocks

- Small & Medium sized CMMs

- CRYSTA-Apex V - 500, 700, & 900 Series

- CRYSTA-Apex V - 1200, 1600 & 2000 Series

- CRYSTA-Apex EX Series for REVO

- STRATO-Active Series

- STRATO-Apex - 500, 700, & 900 Series

- STRATO-Apex - 1600 Series

- LEGEX Series

- Styli

- Styli Kits

- Straight Styli

- Diamond Coated Styli

- Solid Diamond Styli

- Master Ball

- Machine Tool Styli

- Star Styli

- Styli for Star Styli

- Styli for Clamping Holder

- Cylinder Styli

- Disk Styli

- Tip Styli

- Extensions

- Holders

- Adapters

- Joints

- Screws for Cubes

- Tools

- StyliCleaner

- Fixtures

- CMM Fixturing Kits

- Eco-fix Pallet Receiver System Kits

- FixtureBuilder Software

- Eco-fix and Eco-fixplus Extension Sets

- Eco-fix and Eco-fixplus Components

- Eco-fix Screws and Tools

- 3D CNC Vision Systems

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

- Accessories for Vision Machines

- Objective Lenses and Calibration Charts

- QV Index

- Accessories for TP-Retrofit

- Vision System Fixtures

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

- Vision System Styli

- Straight Styli

- Extension

- Star Styli

- Holders

- Styli for 5-way Styli

- Styli for Clamping Holder

- Adapters

- Joints

- Cylinder Styli

- Disk Styli

- Tip Styli

- Screw for Cube

- Tools

- Styli Kits

- Measuring Projectors

- PJ Series

- PV Series

- PH Series

- Data Processing Unit

- Accessories

- Accuracy Inspection Tools

- Measuring Microscopes

- TM Series Gen. B

- MF Series Gen. D

- MF-U Series Gen. D

- Illumination Sources

- Vision Unit

- QSPAK-VUE Software

- Microscope Cameras

- Objective Lenses

- ML-Series Objectives

- Brightfield Observation Objectives

- Brightfield/Darkfield Observation Objectives

- NIR Objectives

- NIR LCD Objectives

- NUV Objectives

- NUV LCD Objectives

- UV Objectives

- UV LCD Objectives

- Interferometer Objectives

- Optical Measurement Fixtures

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

- Surface Roughness

- Surftest SJ-220

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SV-2100

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Surface Roughness & Contour

- Formtracer Avant FTA-D3000 / FTA-D4000 Series

- Formtracer Avant FTA-H3000

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Type 1

- Formtracer Extreme CS-5000CNC and CS-H5000CNC

- Portable Hardness Testers

- Impact Type Hardness Testing Unit HARDMATIC HH-V400

- Digital and Analogue Durometers HARDMATIC HH-300

- Hardness Reference Materials and Indenters

- Hardness reference materials

- Hardness indenters and replacement balls

- Rockwell Hardness Testing Machines

- Manual Rockwell Hardness Testing Machines

- Semi-automatic Rockwell Hardness Testing Machines

- Automatic Rockwell Hardness Testing Machines

- Semi automatic Rockwell bundles

- Vickers Hardness Testing Machines

- Manual Vickers Hardness Testing Machines

- Semi-automatic Vickers Hardness Testing Machines

- Automatic Vickers Hardness Testing Machines

- Micro-Vickers Hardness Testing Machines

- Manual Micro-Vickers Hardness Testing Machines

- Semi-automatic Micro-Vickers Hardness Testing Machines

- Automatic Micro-Vickers Hardness Testing Machines

- Linear Gauges

- ABSOLUTE Digimatic Linear Gauge LGS Series

- Air Drive Unit

- Linear Gauge LG100 Series

- Linear Gauge LG200 Series

- Laser Hologauge

- Counters and Display Units

- EJ Counter and Interfaces for Linear Gauges

- EC Counter for Linear Gauges

- EG Counter for Linear Gauges

- EH Counter for Linear Gauges

- EV Counter for Linear Gauges

- Display Unit for EV Counter

- Laser Scan Micrometers

- Laser Scan Micrometer Measuring Unit

- Laser Scan Micrometer Controller Unit

- Laser Scan Micrometer Interface Unit

- Laser Scan Micrometer Optional Accessories

- DRO Linear Scales and Counters

- DRO Linear Scales AT103

- DRO Linear Scales AT103 - High Accuracy

- DRO Linear Scales AT113

- DRO Linear Scales AT113 - High Accuracy

- DRO ABS Linear Scales AT715

- Universal DRO KA-200 Counter

- DRO ABS Linear Scales AT715 bundles

- NC Linear Scales

- NC Linear Scales ST36

- NC Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- Scale Units

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

- Signal Cables

- USB Input Tool Direct (Digimatic-USB Cable)

- Digimatic Data Cables

- Digimatic Extension Cables

- Wireless Communication

- Wireless Communication System U-WAVE

- U-WAVE Bluetooth

- U-WAVE-T Connection Cables and Connection Units

Aerospace

Aerospace

Complex aerospace applications need fast, extremely precise quality control to ensure accurate assemblies. See how Mitutoyo makes it happen

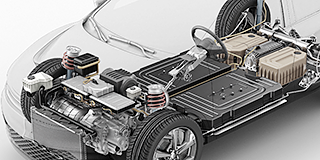

Automotive

Automotive

The automotive industry continues to innovate, and Mitutoyo delivers the advanced inspection and scanning capabilities to help manufacturers achieve ongoing production

Energy

Energy

Mitutoyo’s measurement and analysis solutions are designed to help energy providers improve reliability and increase equipment uptime.

Medical

Medical

To protect patient well-being, medical applications require exceptional accuracy. See how extensively tested solutions from Mitutoyo can help you achieve it.

Gen. Manufacturing

Gen. Manufacturing

Ensure high repeatability and rigorous quality control with form measurement solutions, coordinate measuring machines and precision measuring tools from Mitutoyo.

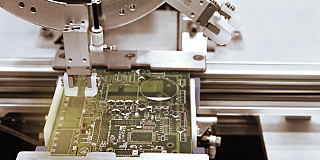

Electronics

Electronics

The non-contact and vision measurement solutions from Mitutoyo bring microscopic accuracy to smaller and denser electronic components

Original Equipment Manufacturers (OEM)

Original Equipment Manufacturers (OEM)

Mitutoyo OEM can address missing expertise or resources by supplying you with our renowned Metrology equipment that seamlessly integrates into your products.

Case Studies

Case Studies

For an overview of Mitutoyo's capabilities, this is no greater place to look than our marvelous collection of case studies.

Mitutoyo Japan Desk

Mitutoyo Japan Desk

The first stop for Japanese companies operating in Europe

Custom Products

Custom Products

Custom-made products for unique applications

Manufacturing Automation Integration

Manufacturing Automation Integration

Turn your factory into a smart factory with the help of Mitutoyo

Mitutoyo Integrators

Mitutoyo Integrators

Integrating your measuring devices into existing processes made easy

Repairs & Spare Parts

Repairs & Spare Parts

Spare parts and repairs for Mitutoyo devices

Calibration

Calibration

Get your measuring devices calibrated by a lab you trust

Field Services

Field Services

On-site service of your favorite measurement and testing machines

Measurement Services

Measurement Services

Get your workpieces and parts measured from anywhere in Europe

Metrology and Product Training

Metrology and Product Training

The quickest way to get support or training

Product Demos

Product Demos

Online or offline, get a product demonstration today

IT Support

IT Support

Perfect and hassle-free installation and integration into your IT infrastructure.

Education Pack

Education Pack

Perfect for the workshop or classroom, there is no greater help than posters or learning material from Mitutoyo

E-Learning

E-Learning

For those interested in metrology, Mitutoyo offers E-Learning courses to help train students, staff, or even hobbyists

Online Material

Online Material

If you're looking for a quick way to learn more about measurement, check out our many instructional videos.

Discover Mitutoyo

Discover Mitutoyo

Unmatched expertise in measurement

Mitutoyo Partners

Mitutoyo Partners

Find out here who our Dealer Partners in Europe are

Certifications & Legitimacy

Certifications & Legitimacy

Here you can explore our certifications, accreditations and legitimacy to ensure trusted and verified services

Career

Career

Learn more about how it feels to work at Mitutoyo and the next steps toward starting your career here

Merchandising

Merchandising

The popular destination for high-quality Mitutoyo apparel and more!

Sustainability

Sustainability

Find out more about Mitutoyo's contribution towards Sustainability

Declarations of Conformity

Declarations of Conformity

Here you can download the full versions for the EU and the UK

Free Wallpapers

Free Wallpapers

Download official Mitutoyo wallpapers here for free

Mitutoyo Brand Communication Materials

Mitutoyo Brand Communication Materials

Resources for Mitutoyo staff and external suppliers

Online Catalog

Online Catalog

View our extensive product range in our online catalog!

-

Products

- Back Products

- Products

- Product Highlights

- Products by Industry

-

Small Tools

- Back Small Tools All Small Tools

- Calipers

-

Micrometers & Micrometer heads

- Back Micrometers & Micrometer heads Micrometers & Micrometer heads

- Digital & Mechanical Micrometers

- Micrometer Accessories

- Micrometer Heads

- Micrometer Head Accessories

-

Inside Measuring Instruments

- Back Inside Measuring Instruments Inside Measuring Instruments

- Inside Micrometers

- Bore Gauges

- Inside Micrometer & Bore Gauge Accessories

-

Depth Measuring Instruments

- Back Depth Measuring Instruments Depth Measuring Instruments

- Depth Micrometers

- Depth Calipers & Gauges

- Depth Caliper Accessories

- Height Gauges

- Indicators & Caliper Gauges

-

Auxiliary Equipment and Miscellaneous

- Back Auxiliary Equipment and Miscellaneous Auxiliary Equipment and Miscellaneous

- Indicator Stands

- Precision Vices

- Plates and Granite Squares

- Angle Measurement and Squares

- Feeler Gauges, Rules, Knife Edges

-

Calibration Instruments

- Back Calibration Instruments Calibration Instruments

- Height Masters

- Check Masters

- Calibration Tools

- Gauge Blocks

-

CMM

- Back CMM All CMM

- Small & Medium sized CMMs

-

In-line & Shopfloor CMMs

- Back In-line & Shopfloor CMMs In-line & Shopfloor CMMs

- MACH Ko-ga-me

- MACH 3A 653

- MACH V 9106

- MiSTAR 555

-

Large sized CMMs

- Back Large sized CMMs Large sized CMMs

- STRATO Apex G

- CARB-Series

-

CMM Rotary Tables

- Back CMM Rotary Tables CMM Rotary Tables

- MRT240 Rotary Table

- MRT320 Rotary Table

- Probes

- Styli

- Fixtures

-

CMM Accessories

- Back CMM Accessories CMM Accessories

- Enclosures

- Security System

-

CMM Software

- Back CMM Software CMM Software

- MiCAT Planner

- MCOSMOS

- MAFIS Express

- MSURF

- GEARPAK EXPRESS

- SmartMeasure-AL

-

Vision

- Back Vision All Vision

- Manual 2D Vision Measuring Machines QM-Fit

-

Manual 2D Vision Measuring Machines Quick Image

- Back Manual 2D Vision Measuring Machines Quick Image Manual 2D Vision Measuring Machines Quick Image

- Quick Image

- Quick Image Software

-

Manual 3D Vision Systems

- Back Manual 3D Vision Systems Manual 3D Vision Systems

- Manual Quick Scope

- Quick Scope Software

-

3D CNC Vision Systems

- Back 3D CNC Vision Systems 3D CNC Vision Systems

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

-

3D CNC Multi-sensor Vision Systems

- Back 3D CNC Multi-sensor Vision Systems 3D CNC Multi-sensor Vision Systems

- Quick Vision Hybrid

- Quick Vision WLI

-

3D CNC Micro Geometry Vision Systems

- Back 3D CNC Micro Geometry Vision Systems 3D CNC Micro Geometry Vision Systems

- UMAP Vision Systems

- UMAP Software

-

Vision System Software

- Back Vision System Software Vision System Software

- QVPAK

- QSPAK

- QIPAK

-

Accessories for Vision Machines

- Back Accessories for Vision Machines Accessories for Vision Machines

- Objective Lenses and Calibration Charts

- QV Index

- Accessories for TP-Retrofit

-

Vision System Fixtures

- Back Vision System Fixtures Vision System Fixtures

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

- Vision System Styli

-

Optical

- Back Optical All Optical

-

Magnifiers

- Back Magnifiers Magnifiers

- Clear Loupes

-

Measuring Projectors

- Back Measuring Projectors Measuring Projectors

- PJ Series

- PV Series

- PH Series

- Data Processing Unit

- Accessories

- Accuracy Inspection Tools

- Measuring Microscopes

-

Microscope Units

- Back Microscope Units Microscope Units

- Microscope Unit FS70 Series

- Video Microscope Unit VMU Series

- Interferometer Units

- Objective Lenses

- M2 for Measuring Microscopes and Projectors

- TAGLENS

-

Optical Measurement Fixtures

- Back Optical Measurement Fixtures Optical Measurement Fixtures

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

-

Form

- Back Form All Form

- Surface Roughness

- Contour

- Surface Roughness & Contour

-

Form

- Back Form Form

- Roundtest

- Roundtracer

-

FMI Software

- Back FMI Software FMI Software

- Formtracepak

- Roundpak

- MCube Map V9

-

Fixtures

- Back Fixtures Fixtures

- Eco-fix FMI Kits

-

Hardness

- Back Hardness All Hardness

-

Softwares for Hardness Testing Machines

- Back Softwares for Hardness Testing Machines Softwares for Hardness Testing Machines

- AVPAK

- Portable Hardness Testers

-

Hardness Reference Materials and Indenters

- Back Hardness Reference Materials and Indenters Hardness Reference Materials and Indenters

- Hardness reference materials

- Hardness indenters and replacement balls

- Rockwell Hardness Testing Machines

- Vickers Hardness Testing Machines

- Micro-Vickers Hardness Testing Machines

- Sensors

-

Digital Scales

- Back Digital Scales All Digital Scales

- DRO Linear Scales and Counters

- NC Linear Scales

-

Scale Units

- Back Scale Units Scale Units

- Horizontal ABSOLUTE Scale Coolant Proof IP66

- Horizontal ABSOLUTE Scale Standard

- Horizontal ABSOLUTE Scale Measurement Direction Switching

- Horizontal ABSOLUTE Scale Diameter Function

- Vertical ABSOLUTE Scale Standard

- Vertical ABSOLUTE Scale Measurement Direction Switching

- Vertical ABSOLUTE Scale Diameter Function

-

Data Management

- Back Data Management All Data Management

-

Data Management Software

- Back Data Management Software Data Management Software

- MeasurLink 10

- USB-ITPAK

-

Mini Processors

- Back Mini Processors Mini Processors

- Digimatic Mini Processor DP-1VA LOGGER

- Signal Cables

- Wireless Communication

- Interfaces

-

Timerbox, Digimatic Switch Box

- Back Timerbox, Digimatic Switch Box Timerbox, Digimatic Switch Box

- Digimatic Timerbox

- Digimatic Switch Box

-

Software

- Back Software All Software

-

CMM Software

- Back CMM Software CMM Software

- MiCAT Planner

- MCOSMOS

- MAFIS-Express

- MSURF

- GEARPAK EXPRESS

-

Vision System Software

- Back Vision System Software Vision System Software

- QVPAK

- QSPAK

- QIPAK

-

FMI Software

- Back FMI Software FMI Software

- Formtracepak

- Roundpak

- MCube Map V9

- Hardness Testing Software

- Sensor Management Software

-

Data Management Software

- Back Data Management Software Data Management Software

- Measurlink 10

- USB-ITPAK

- Automated Measuring Devices

- Computed Tomography Systems

- Industries

-

Services

- Back Services

- Services

- Mitutoyo Japan Desk

-

Smart Factory Solutions

- Back Smart Factory Solutions

- Smart Factory Solutions

- Custom Products

- Manufacturing Automation Integration

- Mitutoyo Integrators

- Repairs & Spare Parts

- Calibration

- Field Services

- Measurement Services

- Metrology and Product Training

- Product Demos

- IT Support

-

Education

- Back Education

- Education

- Education Pack

- E-Learning

- Online Material

-

About us

- Back About us

- About us

-

Discover Mitutoyo

- Back Discover Mitutoyo

- Discover Mitutoyo

-

Mitutoyo History

- Back Mitutoyo History

- Mitutoyo History

- Name & Philosophy

- Mitutoyo Corporation

- Mitutoyo in Europe

-

Mitutoyo 90th Anniversary

- Back Mitutoyo 90th Anniversary

- Mitutoyo 90th Anniversary

-

Mitutoyo Partners

- Back Mitutoyo Partners

- Mitutoyo Partners

- Mitutoyo Spain

- Mitutoyo Portugal

- Mitutoyo Turkey

-

Certifications & Legitimacy

- Back Certifications & Legitimacy

- Certifications & Legitimacy

- Certifications & Accreditations

- Products Legitimacy (FAKE)

-

Career

- Back Career

- Career

- Mitutoyo Trainee Program

- Merchandising

- Sustainability

-

News

- Back News

- News

- Events

-

Special Promotions

- Back Special Promotions

- Special Promotions

- Press Area

- Downloads

Mitutoyo's measuring instruments are the key to the taste of pasta

Pasta, an iconic Italian delicacy adored worldwide, relies on stringent quality control measures to preserve its irresistible flavor and ensure culinary perfection. This article will focus on Mitutoyo's role in pasta production and explore its importance and impact.

Dies to determine the shape of pasta

Strict quality control required for dies

Pasta has been eaten in Japan since the Edo period. As you know, it is now available in a variety of shapes, with over 500 varieties. The key part that determines the shape of pasta is the mold of a special pasta making machine (extrusion type) called a "die".

There are two types of dies: bronze and Teflon, the former giving the pasta a rough finish, and the latter giving it a smooth, silky finish. Texture is a key factor in the flavor of pasta, so manufacturers subject it to strict quality control.

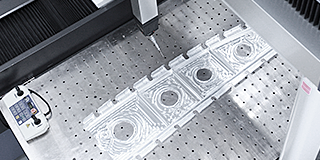

Pasta dough being pushed out of the die to form noodles

Does the deterioration of the dice affect the taste?

The crucial part, the dice, is at risk of wear and deformation after prolonged use, so they require regular cleaning and maintenance. Bronze dies are particularly prone to deterioration over time.

Pasta production requires precision, as even slight changes in the diameter or shape of the die holes can diminish the inherent flavor and taste of the wheat.

This is where Mitutoyo's "measuring microscopes" come in handy.

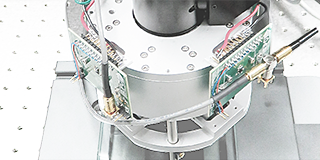

Measuring microscopes are also used for die maintenance

Consistency in pasta production

Mitutoyo measuring instruments are widely used in manufacturing industries around the world due to their precision and durability. However, what is less known is that Mitutoyo, which has established itself as a leading company in the field of measuring instruments for over 90 years, is also used in the food industry.

The greatest feature of the measuring microscopes used in die maintenance is their ability to measure minute surface characteristics and shapes with a high degree of precision, which makes it possible to accurately grasp changes caused by aging and maintain product quality.

In other words, Mitutoyo measuring instruments can be called important tools for producing consistent products.

A small surface roughness measuring instrument used in final inspection

Mitutoyo products for final inspection

Pasta extruded through a die generally undergoes a drying, cooling, and cutting process before a final inspection, and here too a Mitutoyo product is used - a measuring device called a "surface roughness measuring instrument".

Food manufacturers measure various items before weighing and packaging the finished pasta to determine whether it meets the standards set by the company, and the roughness of the pasta surface is one of them.

Mitutoyo's surface roughness measuring instruments are easy to handle due to their handy design and excellent operability, so many major manufacturers use them. Undoubtedly, they play a major role in pasta manufacturing, along with measuring microscopes.