- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

Mitutoyo realizes this and offers classroom training, eLearning, virtual training, and on-demand resources across a wide variety of measurement-related topics to get you the training and education you need. See our certified wide range of product and software training for Mitutoyo measuring equipment, including CMM, vision, and form products, and also the huge variety of courses in the Metrology foundation.

Mitutoyo offers professional product and software training and education courses at our M3 Solution Centers across the country. The classroom courses are taught by experienced educators with expert technical knowledge in inspection techniques, principles of dimensional metrology, calibration methods, and quality concepts using a hands-on experiential style that engages students and doesn’t bore them with lectures.

Live virtual instruction is an option for much of the training and education content offered by Mitutoyo. From CMM software training to micrometer calibration, virtual courses allow you direct access, with no travel expenses, to our technical experts regardless of location. Virtual courses allow low-cost access to technical training.

All courses are delivered by highly skilled engineers. Our metrology experts in the education department provide a wide range of resources and educational opportunities across the measurement science field. Through the worldwide operations of Mitutoyo, we are the premier training and education provider within the quality field.

Many classroom courses offered by Mitutoyo can be customized to your specific needs and also brought to your location. On-site courses are well suited when travel is challenging or for a larger group of students within an organization. Our instructors will work with you in advance to build an on-site course experience that best addresses your training and education needs.

In response to customer demand, Mitutoyo offers the opportunity to earn Certified Credentials that can validate your knowledge and demonstrate your measuring skill. Our credentials are a great way to impress an auditor or a customer or a potential employer.

Certified Courses are either available with a unique "Mitutoyo Institute of Metrology" Diploma and/or with official Certification by AUKOM in selected Countries.

• Training your staff will result in a more effective and efficient workforce.

• Increased work satisfaction leading to higher staff retention.

• Enhancing in-house knowledge will improve your company’s ability to adopt and use advances in technology.

• Enhance your company’s reputation and standing as a progressive and responsible employer.

Coordinate Measuring Machine Software Courses

> Coordinate Metrology Trainings

> Level 1 / Operator

> AUKOM 1

The seminar imparts and consolidates basic production metrology knowledge for beginners and advanced metrologists - following the latest didactic knowledge on the subject of dimensional tolerances, programming basics, Measuring sequence planning as well as the machine and sensor technology to be used.

A better understanding of the measurement tasks and Influencing factors enable the measurement technician to reduce measurement uncertainties and thus make measurement results more reliable and more comparable - which results in the minimization of costs and waste.

Course Content

Units

Coordinate systems

Coordinate measuring machines

Sensors of coordinate measuring machines

Metrological basics

Dimensional tolerance

Geometric elements

Geometric links

Preparing a measurement on the coordinate measuring machine

Select and measure sensors

Measure with the coordinate measuring machine

Evaluate measurements and statistics

Test planning

Documentation and quality management

>Target Group: Production measurement technicians

>Prerequisites: None

>Course Duration: 5 days

>Diploma: Exam (AUKOM Level 1) / Certificate (MiM)

This course is available with Mitutoyo Institute of Metrology Diploma and/or with official Certification by AUKOM in selected Countries.

> Coordinate Metrology Trainings

> Level 2 / User

> AUKOM 2

Course Content

Overview of the entire measurement process

Geometry overview

Shape and position tolerance

Measurement strategy

Probing strategy - Tactile sensors

Probing strategy - Image processing sensors

Probing strategy - distance sensors

Computed tomography

CNC programming

Measure freeform surfaces

Evaluate

Influences on the measurement result

Documentation

The culture of professional measurements

>Target Group: Production measurement technicians

>Prerequisites: Successful pass of MiM Certification Level 1 / Operator

or AUKOM Level 1 Exam

>Course Duration: 5 days

>Diploma: Exam (AUKOM Level 2) / Certificate (MiM)

This course is available with Mitutoyo Institute of Metrology Diploma and/or with official Certification by AUKOM in selected Countries.

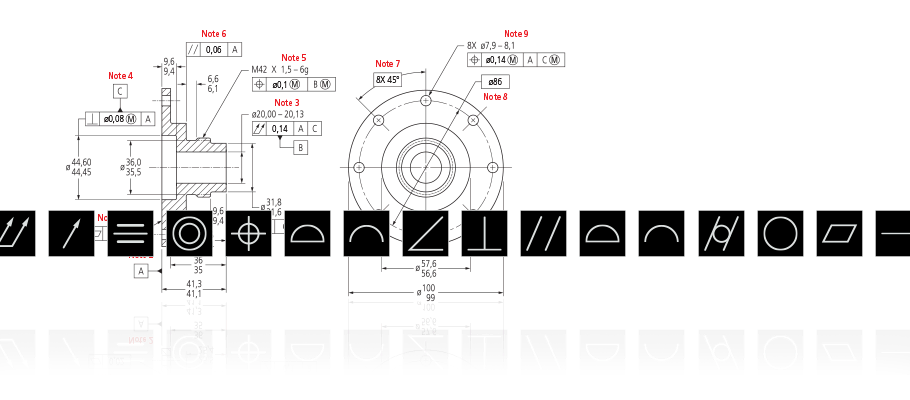

> Coordinate Metrology Trainings

> Geometric Dimensioning and Tolerancing

> AUKOM GD&T

This seminar offers in-depth knowledge on shape and position tolerances according to DIN ISO and ASME for advanced Measurement technicians who work at the interfaces to other departments and must communicate profitably.

Designers, Developers, and production technicians get an insight into the topic of shape and position tolerances from the point of view of the measurement technician and a holistic understanding of the measurement tasks and Influencing factors.

Measurement results become more reliable and comparable. The minimization of costs and waste is supported.

Course Content

Basics of the system of geometric product specification

Function, specification, verification, terms

Form tolerances

Dimensions and angles

References and reference systems

Positional tolerances

Profile tolerances

Maximum material requirement

Minimum material condition and reciprocity condition (ISO)

Verification

>Target Group: Production measurement technicians, Production technicians,

Developers, Designers, QA managers

>Prerequisites: For production measurement technicians: certificate

Training Coordinate Metrology Level 2 / User or AUKOM Level 2 Exam recommended;

for other target groups: none

>Course Duration: 3 days / 5 days

>Diploma: Certificate (MiM)

This course is available with Mitutoyo Institute of Metrology Diploma and/or with official Certification by AUKOM in selected Countries.

> Coordinate Metrology Trainings

> Level 3 / Expert

> AUKOM 3

The seminar offers comprehensive production metrology knowledge for advanced metrologists collaborating with other departments.

It is based on the most modern didactic knowledge and offers the latest knowledge on functional and production-oriented measurement, filtering, program creation, Computer tomography, QM, and measuring room management.

A comprehensive understanding of the measurement tasks and influencing variables enable the experts to communicate securely with interdepartmental bodies and reduce measurement uncertainties, Measurement results become more reliable and comparable. The minimization of costs and waste is supported.

Course Content

Comparable geometry specification suitable for testing

Production-oriented testing

Basic knowledge – CAD

Point clouds and reverse engineering

Automated measurement program creation (PMI)

Digital filtering and evaluation

Communication

Sensor competence

Monitoring of CMMs

Measurement uncertainty and test process suitability

Quality management

Process monitoring and statistics

Measurement room management

>Target Group: Production metrologists, metrology room managers, QA leaders

>Prerequisites: Successful Training Coordinate Metrology Level 2 / User and Training Geometrical Deviations and Tolerances required

>Course Duration: 5 days

>Diploma: Exam (AUKOM Level 1) / Certificate (MiM)

This course is available with Mitutoyo Institute of Metrology Diploma and/or with official Certification by AUKOM in selected Countries.

> Measurement Technician

> Update-Training

> AUKOM Metrologist Update

Update your knowledge on form and position tolerances, sensor technology, measurement strategy, PMI, and sensor technology in this 2-days intensive course.

Course Content

Standard definitions, innovations in dimension, shape, and position according to ISO 1101, 14405, and more

Evaluation methods and modifiers

Reference formation

Verification of shape and position tolerances

Similarities and differences in ISO and ASME, Principles

Fringe projection, photogrammetry computer tomography, and more

Dealing with different sensors

Creation of measurement strategies

Usage and requirements for the use of filters and compensation algorithms

PMI update, challenges

>Target Group: Production measurement technicians

>Prerequisites: Successful participation in Training Coordinate Metrology Level 1, Level 2, Level 3, or Geometrical Deviations and Tolerances. AUKOM 1, AUKOM 2, AUKOM 3 or AUKOM Geometrical Deviations and Tolerances.

>Course Duration: 2 days

>Diploma: Certificate (MiM) for seminar participation and

additionally, the certificate AUKOM measuring technician

This course is available with Mitutoyo Institute of Metrology Diploma and/or with official Certification by AUKOM in selected Countries.

> Basic Software Training - MCOSMOS/GEOPAK Manual CMM

Learn how to successfully process simple measurement tasks with a manual Coordinate measuring machine, such as three-dimensional geometry measurement of various workpieces dated Design to completion with GEOPAK, Mitutoyo's universal software.

Course Content

Switching on, operating the entire system, special features

Measuring head systems, handling, setting instructions, special features

Calibration of the measuring head system or the sensor

Creation of different coordinate systems, handling, particularities

Standard geometric elements (e.g. plane, circle, line, point, cylinder, etc.)

Position measurements

Distance measurements

Angle measurements

Links of geometric elements such as Connection elements, cutting elements, symmetry elements

Application of form and position tolerances in GEOPAK

Evaluation and output of the geometry data

Creation of a measurement program in learning mode

Changing a measurement program in edit mode

Manual repeat operation

Handling of a measuring program in the part manager

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise, Training Coordinate Metrology Level 1 / Operator or Aukom 1 is recommended, Experience in using a PC (Windows operating system)

>Course Duration: 3 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo MCOSMOS / GEOPAK for CNC CMM

Learn how to successfully process simple measuring tasks with a CNC-controlled Coordinate measuring machine, such as three-dimensional geometry measurement of various workpieces dated Design to completion with GEOPAK, Mitutoyo's universal software.

Course Content

Switching on, operating the entire system, special features

Measuring head systems, handling, setting instructions, special features

Calibration of the measuring head system or the sensor

Creation of different coordinate systems, handling, particularities

Standard geometric elements (e.g. plane, circle, line, point, cylinder, etc.)

Position measurements

Distance measurements

Angle measurements

Links of geometric elements such as Connection elements, cutting elements, symmetry elements

Application of form and position tolerances in GEOPAK

Evaluation and output of the geometry data in the target/actual

comparison of the printer and in file

Creation of a CNC measuring program in learning mode

Changing a CNC measuring program in edit mode

CNC - repeat operation

Handling a CNC measuring program in the part manager

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise, successful participation Training Coordinate Metrology Level 1 or AUKOM 1 recommended, experience in using a PC (Windows operating system)

>Course Duration: 5 days / 4 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo MCOSMOS / CAT1000S for Manual

Coordinate Measuring Machines

Learn how to perform and evaluate simple freeform surface measurements with datasets in Mitutoyo CAT1000S, a 3D freeform surface evaluation module for the precise comparison of spatially curved surfaces with the Target specifications from the CAD data.

Course Content

Import data set

Analysis of the data set

Determine alignment elements from the data set

Determine and calibrate the configuration of the measuring head system

Alignment of the workpiece based on the data set

Best fit, RPS alignment, transform model

Settings: Hide planes and edges

Freeform surface measurements

Archive, mark, and hide measurement points

Log outputs of the views and the active measurement points

Creation of a measurement program in learning mode with GEOPAK

and CAT1000S

Test of the created program in repeat operation

>Target Group: Production measurement technicians

>Prerequisites: Successful participation MCOSMOS / GEOPAK Basic Training, Training Coordinate Metrology Level 2 or AUKOM 2 recommended

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo

MCOSMOS / CAT1000P for CNC CMM

This course enables you to carry out simple measurement tasks in online/offline operations to solve data sets and a CNC-CMM. CAT1000P is an on/offline programming module for the easy creation of geometry measuring programs on the CAD data set.

The time-consuming input of the drawing parameters for all elements is replaced by a few mouse clicks on a CAD model.

Course Content

Import model, analysis of the data set, possible CAD formats, handling

Model handling in the CAD window

Determine the machine configuration and calibrate the measuring head system

Change CAD coordinate system, procedure, special features

Alignment of the workpiece based on the data set

Settings: clearance height, movement box, collision protection

Element dialogs (e.g. plane, circle, line, point, cylinder, etc.)

Coordinate measurement of geometric elements

Creation of a CNC measuring program in online/offline learning mode

Simulating the complete parts program

Handling of a CNC measuring program created in online or offline mode

Repeating the CNC measuring program created in online or offline mode

Setting options and user tips

>Target Group: Production measurement technicians

>Prerequisites: Successful participation Training MCOSMOS / GEOPAK Basic Training, Coordinate Metrology Level 2 or AUKOM 2 is recommended.

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo MCOSMOS / SCANPAK for CNC CMM

Learn how to carry out simple 2-D contour comparisons with the coordinate measuring machine. SCANPAK is a 2D contour evaluation module for recording and evaluating deviations between nominal contours and captured contours.

Course Content

Manual and/or CNC contour recording

Editing contour

Create geometric elements and calculate them from the contour

Contour comparison (nominal/actual comparison)

Export and import contours

Useful examples

>Target Group: Production measurement technicians

>Prerequisites: Successful participation Training MCOSMOS / GEOPAK Basic Training, Coordinate Metrology Level 2 or AUKOM 2 is recommended.

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo

MCOSMOS / GEARPAK for CNC CMM

Learn how to measure simple straight and helical spur gears with the 3D CNC coordinate measuring machine. GEARPAK is a measurement and evaluation module for involute gears, which, in addition to the fast generation of measuring programs also takes over the comprehensive evaluation and logging of the gear measurement.

>Target Group: Production measurement technicians

>Prerequisites: Successful participation in Training MCOSMOS / GEOPAK basic training, Coordinate Metrology Level 2 or AUKOM 2 is recommended.

>Course Duration: 1 day

>Diploma: Certificate (MiM)

Course Content

Defining and calibrating the measuring head system

Creating a coordinate system in GEOPAK

Define and enter gear parameters in GEARPAK

Part program creation by GEARPAK

Measuring with GEOPAK

Evaluation and output of the measurement results with GEARPAK

Useful examples

Vision Measuring Machine Software Courses

> Basic Software Training - Mitutoyo

QIPAK for Vision Measuring Machines

Learn simple measuring tasks, such as single and repeated measurements for image processing measuring devices from the Mitutoyo with the operating software QIPAK.

Course Content

Switching on, operating the entire system, special features

Interface of the software QI-Pak

Creation of different coordinate systems, handling, particularities

Image processing tools, edge detection, Setting options, special features

Standard geometric elements (e.g. circle, line, point)

Distance measurement

Angle measurement

Symmetry elements

Links of geometric elements such as distance and cut elements

Single measurement

Creation of a measurement program in recording mode

Editing of measurement programs

Repetition of a measurement program

Storing video images, image documentation

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo

QSPAK for QUICK SCOPE series

Master simple measuring tasks, such as single and repeated measurements, on the image processing measuring device QUICK SCOPE series by Mitutoyo with the help of the operating software QSPAK.

Course Content

Switching on, operating the entire system, special features

QSPAK software interface

Creation of different coordinate systems, handling, particularities

Image processing tools, edge detection, setting options, particularities

Standard geometric elements (e.g. plane, circle, line, point)

Distance measurement

Symmetry elements

Angle measurement

Plane measurement

Links of geometric elements such as distance and cut elements

Creating and working with templates

Single measurement

Creation of a measurement program in recording mode

Editing of measurement programs

Repeat a measurement program

Save video images, image documentation

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo

QVPAK for QUICK VISION series

Learn simple measuring tasks, such as single and repeated measurements, on image processing measuring devices from the Mitutoyo QUICK VISION series with the operating software QVPAK.

Course Content

Switching on, operating the entire system, special features

Interface of the software QVPAK

Creation of different coordinate systems, handling, particularities

Image processing tools, edge detection, setting options, Filters, specifics

Standard geometric elements (e.g. plane, circle, line, point)

Distance measurement

Angle measurement

Symmetry elements

Plane measurement

Links of geometric elements such as distance and cutting elements

Single measurement

Creation of a measurement program in recording mode

Editing of measurement programs

Repeat a measurement program

Save video images, image documentation

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 3 days

>Diploma: Certificate (MiM)

> Basic Software Training - Mitutoyo

QVBasic for QUICK VISION series

Simplify processes and solve simple tasks with QVBasic, the programming language based on Visual Basic. QVBasic is used for image processing systems of the QUICK VISION series.

Gain maximum flexibility - for example when connecting barcode readers, data transfer to MS Office applications, or the creation of user-defined input and query masks.

Course Content

What is QVBasic?

Structure of a QVBasic program

QVBasic Editor user interface

Working with the QVBasic Editor

Variable types

Simple application of number and text variables

Creating loops

Working with conditions

Simple query: The input box

Simple Message: The Msgbox

Linking of QVBasic programs

Bug localization

Queries on various parameters

>Target Group: Production measurement technicians

>Prerequisites: QVPAK basic training,

Coordinate Metrology Level 1 or Aukom 1 is recommended.

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Mitutoyo QSPAK VISION UNIT - Training For MF Measuring Microscopes

Learn simple measuring tasks with the QSPAK VISION UNIT Edition software for the camera unit of Mitutoyo MF measuring microscopes.

Course Content

Switching on, operating the entire system, special features

QSPAK VUE software interface

Creation of different coordinate systems, handling, peculiarities

Image processing tools, edge detection, setting options, special features

Explaining the standard geometric elements (e.g. circle, straight line, point)

Distance measurement

Symmetry elements

Angle measurement

Links of geometric elements such as connecting and cutting elements

Single measurement

Creation of a measurement program in recording mode

Editing of measurement programs

Repeat a measurement program

Create and save video images, image documentation

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Basic Software Training - FORMPAK-QV

for QIPAK, QSPAK, QVPAK and VISION UNIT

Create and evaluate simple contours with FORMPAK-QV, Mitutoyo's efficient program for contour analysis. FORMPAK-QV is used for image processing systems QUICK IMAGE, QUICK SCOPE, QUICK-VISION, and VISION UNIT.

Course Content

FORMPAK-QV in conjunction with QIPAK, QSPAK, QVPAK, VISION UNIT

Contour recording, setting the measurement conditions

Geometric contour evaluation

Layout creation

Alignment

Creation of a part program

If required: 2D contour comparison (will extend training to become 2 days)

>Target Group: Production measurement technicians

>Prerequisites: Basic training QIPAK, QSPAK or QVPAK

Coordinate Metrology Level 1 or Aukom 1 is recommended.

>Course Duration: 1 day (2 days if 2D contour comparison is trained)

>Diploma: Certificate (MiM)

Form Measurement Software and Hardware Courses

> Basic Training ROUNDTEST RA-10

This course enables you to master simple measuring tasks with our compact form and position measuring device ROUNDTEST RA-10.

Course Content

Device operation

Stylus change

Measure probe element

Set measurement conditions

Measurement of various parameters

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise and basics of form and position tolerance and their characteristic values are required, Coordinate Metrology Level 1 or Aukom 1 is recommended,

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Training ROUNDTEST RA-120

From operating the device to simple measurement tasks - Learn everything about our compact form measuring device ROUNDTEST RA-120

Course Content

Device operation

Stylus change

Measure probe element

Center and level

Set measurement conditions

Measurement of various parameters

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise and basics of form and position tolerance and their characteristic values are required, Coordinate Metrology Level 1 or Aukom 1 is recommended,

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Software Training - ROUNDPAK

and ROUNDTEST RA-120P

ROUNDPAK is software that allows you to easily create your specific measurement program, the entire Measurement process visualized and the results documented in clear diagrams and 3D graphics. This course will enable the participants to solve simple measurement tasks with ROUNDPAK on ROUNDTEST RA-120P.

ROUNDPAK is used for form measurement devices RA-120P, RA-1600, RA-2200, and RA-H5200 as well as for CNC devices.

Course Content

Device operation RA-120P

Stylus change

Measure probe element

Center and level

Set measurement conditions

Measurement of various parameters

Evaluation and layout creation

Creation of part programs

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Basic knowledge of Geometrical Deviations and Tolerances,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Software Training ROUNDPAK

and ROUNDTEST RA-1600 (and higher)

Learn how to easily create specific measurement programs with ROUNDPAK and have the entire Measurement process visualized and the results documented in clear diagrams and 3D graphics.

ROUNDPAK is used for form measurement devices RA-120P, RA-1600, RA-2200, and RA-H5200 as well as for the CNC devices.

Course Content

Device operation

Stylus change

Measure probe element and master ball measurement

Workpiece alignment

Center and level

Set measurement conditions

Measurement of various parameters

Evaluation and layout creation

Creation of part programs with movement commands

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Basic knowledge of Geometrical Deviations and Tolerances,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Basic Software Training - FORMTRACEPAK for CV-2100, CV-3200, CV-4500, and FORMTRACER AVANT

Learn how to evaluate and document contour measurement data with FORMTRACEPAK

for the Contracer CV-2100, CV-3200, and CV-4500 contour measuring devices.

Course Content

Device operation

Probe element, probe arm change

Measure probe element

Contour recording, setting the measurement conditions

Geometric contour evaluation

Layout creation

Creation of a part program

If required: 2D contour comparison, connect contours

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Basic knowledge of Geometry,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 2 days

>Diploma: Certificate (MiM)

> Basic Software Training - FORMTRACEPAK for CS-3200

Learn all about FORMTRACEPAK, the Formtracer CS-3200 instrument control software.

This software also takes over the evaluation and documentation of the results and, depending on the system, the control of the CNC axes.

Course Content

Device operation

Stylus change

Measure probe element

Contour recording with setting of the measurement conditions

Geometric contour evaluation

Surface roughness evaluation

Layout creation

Creation of a part program

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Basic knowledge of Geometry,

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 3 days

>Diploma: Certificate (MiM)

> Basic Software Training - FORMTRACEPAK for SV-C3200, SV-C4500, and

Formtracer AVANT series

Learn everything about FORMTRACEPAK, the software for device control of the

Mitutoyo SV-C3200, SV-C4500 and Formtracer AVANT series.

This also takes over the evaluation and documentation of the results and, depending on the system, the control of the CNC axes.

>Target Group: Production measurement technicians

>Prerequisites: Well-founded metrological expertise,

Basic knowledge of Geometry, surface metrology, and their characteristics

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system) is required

>Course Duration: 3 days

>Diploma: Certificate (MiM)

Course Content

Device operation

Measuring system change (contour, surface roughness)

Probe element, probe arm change

Continuous calibration for contour

Calibrate stylus for surface roughness

Contour recording with setting of the measurement conditions

Geometric contour evaluation

Layout creation

Creation of a parts program for contour measurement

Surface roughness measurement

Set measurement and evaluation conditions

Creation of a part program for surface roughness

Integration of movement commands

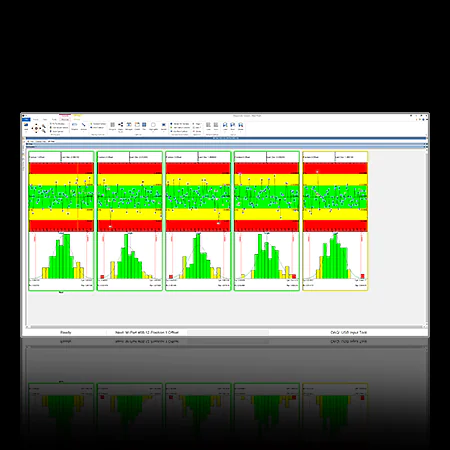

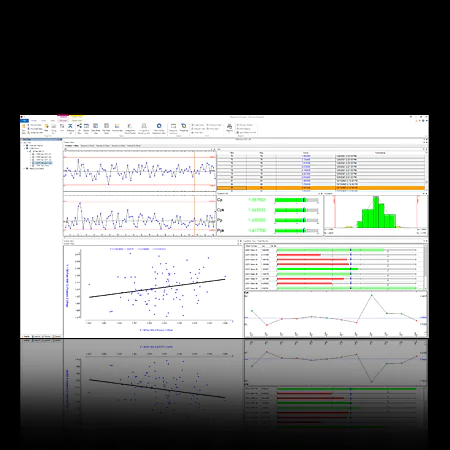

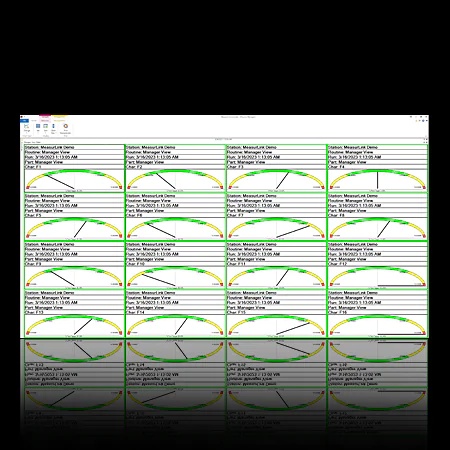

MeasurLink SPC Software Trainings

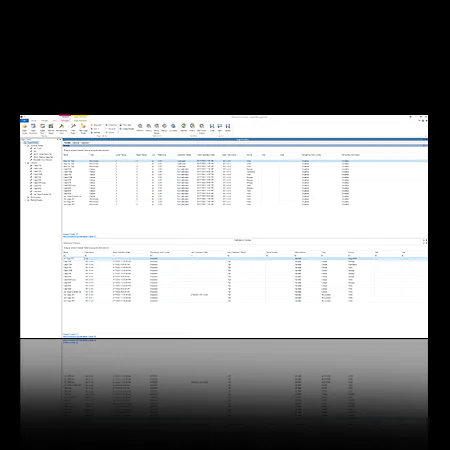

MeasurLink combines Real Time on-line data collection with Real Time SPC charts and analysis for operators and Real Time Quality Control/Supervisor Reports and Alerts for your entire manufacturing system. MeasurLink is designed for integrated networks to create a quality information-sharing system that includes a comprehensive metrology solution for your company.

![]()

Reduce costs associated with inspection, rework, and scrap

![]()

Ensure part quality

and consistency

![]()

Increase data visibility

and accessibility

![]()

Increase ease of use for inspectors

in all environments

![]()

Reduce manufacturing defects through the use of real-time SPC

> MeasurLink Software Training

Module: Support Center/ Real Time

This training enables you to use the MeasurLink Support Center to define what, how, and where to test - and optionally which information serves for traceability.

Real-Time enables real-time data collection from virtually any measuring device: Vernier calipers, micrometers, dial gauges, coordinate measuring machines, image processing systems, and much more.

>Target Group: Measurement technicians, Skilled workers in production,

Quality management specialists, Quality Management Officers

>Prerequisites: Basic statistical knowledge

Additionally - for measuring devices with peripheral software:

Device-specific basic training, e.g. GEOPAK - basic training CNC, QV-PAK, Formtracepak, etc.

Coordinate Metrology Level 1 or Aukom 1 is recommended,

Experience in using a PC (Windows operating system)

>Course Duration: 1 day

>Diploma: Certificate (MiM)

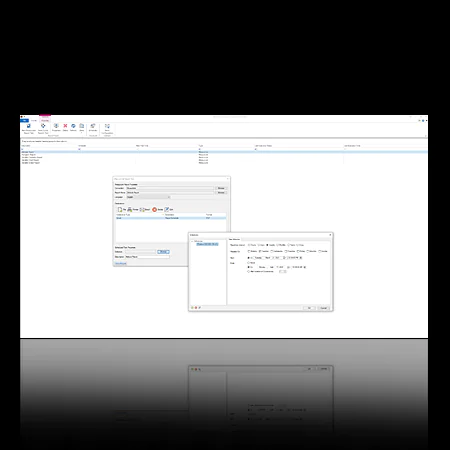

> MeasurLink Software Training

Module: Process Analyzer

Learn how to flexibly analyze processes and identify problem areas with the MeasurLink Process Analyzer

and take appropriate measures to improve the quality of the product.

The Process Analyzer is an invaluable tool for your quality assurance team to organize run data by station, inspection plan, or workpiece. The data can be merged, filtered, grouped, displayed graphically, or printed out in the desired formats.

>Target Group: Measurement technicians, Quality management specialists, Quality management officers

>Prerequisites: Basic statistical knowledge

Experience with real-time data and in using a PC (Windows operating system)

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

> MeasurLink Software Training

Module: Process Manager

The Process Manager is used to display the measurement data in real-time.

Learn to benefit from this optimal tool for permanent Monitoring of the quality in the entire production area.

>Target Group: Measurement technicians, Quality management specialists, Quality management officers

>Prerequisites: Basic statistical knowledge

Experience with real-time data and in using a PC (Windows operating system)

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

> MeasurLink Software Training

Module: Gauge Management

Learn all about Measurlink Gauge Management. This module supports you in the management of test equipment in your company. Benefit from simple logging of usage of measuring devices (use, storage, dunning list, calibration, test equipment capability, repairs, and decommissioning) and a quick overview of the current locations and the status of all your test equipment.

>Target Group: Quality management specialists, Quality Management Officers

>Prerequisites: Experience in using a PC (Windows operating system)

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

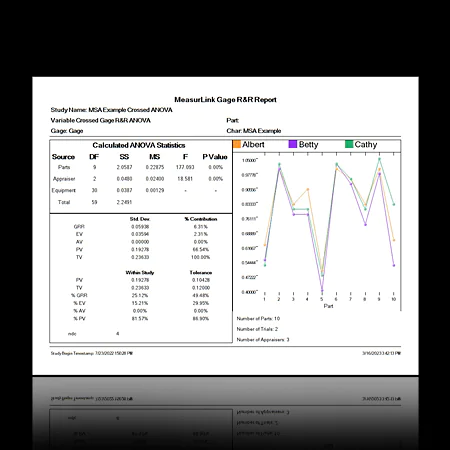

> MeasurLink Software Training

Module: Gauge R&R

Gage R&R includes procedures to determine the capability of a measurement system for a particular measurement task.

Learn how to use Gauge R&R to provide you seamless information about a measurement system’s reproducibility, R&R, location, or stability and set up of graphical tools allowing isolation of gaging problems including inconsistencies in technique between operators or inspectors.

>Target Group: Production managers, Quality management specialists, Quality management officers

>Prerequisites:

Participation MeasurLink Support Center/ Real-Time Training

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

> MeasurLink Software Training

Module: Report Scheduler

Report Scheduler is a tool that provides automated report distribution from a Windows service environment. Learn how to create convenient reporting tasks and have them run on a given schedule.

>Target Group: Measurement technicians, Quality management specialists, Quality Management Officers

>Prerequisites:

Participation MeasurLink Support Center/ Real-Time Training, Knowledge on real-time data, and experience in using a PC (Windows operating system)

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

More Product Trainings

> QM-Data 200 Basic Training - Data Processor for Profile Projectors or Measuring Microscopes

Learn to process data from a profile projector or measuring microscope and transfer the measurement results to the PC spreadsheet program MS Excel in CSV format.

Course Content

Switching on, operating the entire system, special features

Lenses, assembly and disassembly, setting instructions, special features

Creation of different coordinate systems, handling, peculiarities

Explaining the standard geometric elements (e.g. circle, straight line, point, etc.)

Position measurements

Distance measurements

Angle measurements

Links of geometric elements such as connection elements, cutting elements,

Symmetry elements

Application of shape and location

Evaluation and output of the geometry data in a target/actual comparison on printer and in file

Practical measurements on the practice workpiece

Creation of a measurement program in learning mode

Handling a measurement program in edit mode

Running a part program in repeat mode

Explain various function keys and symbols of the data processor.

Optional: Calibration of the Optoeye edge sensor, setting instructions, practical measurement examples with the edge sensor (option)

S>Target Group: Production measurement technicians, Skilled workers in production

>Prerequisites:

Basic knowledge of Geometry,

Coordinate Metrology Level 1 or Aukom 1 is recommended

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> LH-600 Basic Training - Linear Height Gauge

Learn to operate the LH-600, an easy-to-use height gauge with which various basic measurements such as height, inside / external width, internal/external diameter, and much more.

Course Content

Installation and removal of the transport lock

General explanation of the measuring device

Explanation of the software user interface

Calibrate the probe

Basic functions/measurements

>Target Group: Measurement technicians,

Quality management specialists, Quality management officers

>Prerequisites:

Basic knowledge of Metrology and Geometry,

Coordinate Metrology Level 1 or Aukom 1 is recommended

>Course Duration: 1/2 day

>Diploma: Certificate (MiM)

> Hardness Tester Basic Training

Learn the proper handling of Rockwell, Super Rockwell, Brinell, Vickers, or Micro-Vickers hardness testers - and also those of portable Leeb and Shore models.

Course Content

Measurement of customer's parts, including discussion of the evaluation

Discussion of possible sources of error and how to avoid them

>Target Group: Production measurement technicians, Skilled workers in production

>Prerequisites: Basic knowledge of material science

>Course Duration: 1 day

>Diploma: Certificate (MiM)

Seminars and Workshops for Metrology Fundamentals

> Operational practice for

Quality Assurance with Handheld Measuring Devices Seminar

Quality assurance (QA) is a general term for different approaches and measures to ensure

specified quality requirements.

In this seminar, you will learn the advantages of using various Mitutoyo handheld measuring devices for checking the dimensional quality of your products.

Course Content

Basic knowledge and professional usage of Mitutoyo:

• Vernier calipers

• Outside micrometers

• Dial gauges

• Internal gauges

>Target Group: Pupils, Students, Skilled workers, QM specialists, QM representatives

>Prerequisites: Not required

>Course Duration: 1 day

>Diploma: Certificate (MiM)

> Geometrical Deviations and Tolerances in Theory and Practice Workshop

Learn all about GD&T, background knowledge, application in theory (90%), and practical work with related user software (10%).

Course Content

Form tolerances

Straightness

Roundness

Flatness

Cylindricity

Positional tolerances

Basics

References and reference systems

Directional errors - parallelism, squareness, and slope deviation

Spatial errors - position, coaxiality, and symmetry deviation

Run-out deviations - concentricity and axial run-out deviation,

Total run-out and run-out in specified Direction

Profile tolerances

Line and area profile deviation

Tolerance principles

Correlation between dimension, shape, and position tolerances

Height dimensions and distance dimensions

Principle of Independence

Envelope condition

Maximum material condition

Minimum material requirement

General tolerances of shape and position

Summary

>Target Group: Employees who have to deal with drawings and the tolerancing of workpieces - for example, Employees in Development, Quality assurance, Production, procurement, or Production planning.

>Prerequisites: Technical understanding of general mechanical engineering

>Course Duration: 3 days

>Diploma: Certificate (MiM)

> Basics of Surface Roughness Seminar - Measurement Tactile 2D Stylus Method

>Target Group: Employees who deal with drawings and tolerating surface roughness

of workpieces - in Development, Quality assurance, Manufacturing, Procurement, or Production planning.

>Prerequisites: Technical understanding

>Course Duration: 1 day

>Diploma: Certificate (MiM)

Course Content

Shape deviations and profiles (P, W, R)

Lambda filter, gaussian and robust gaussian regression filter

Skid tracing systems vs. datum plane tracing systems

Definition of standard parameters according to DIN EN ISO 4287

Amplitude density curve including characteristic values

Material content according to DIN EN ISO 4287 and 13565-1 and -2

EN 10049

Tactile elements

Measuring conditions according to DIN EN ISO 4288

Impact of Deviations

Drawing entries in ISO and VDA

Differences in ISO and VDA

Scoring Rules 16% and MAX

Exercises